The Importance of Precision Alignment & Vibration Analysis for Machinery Performance

Share

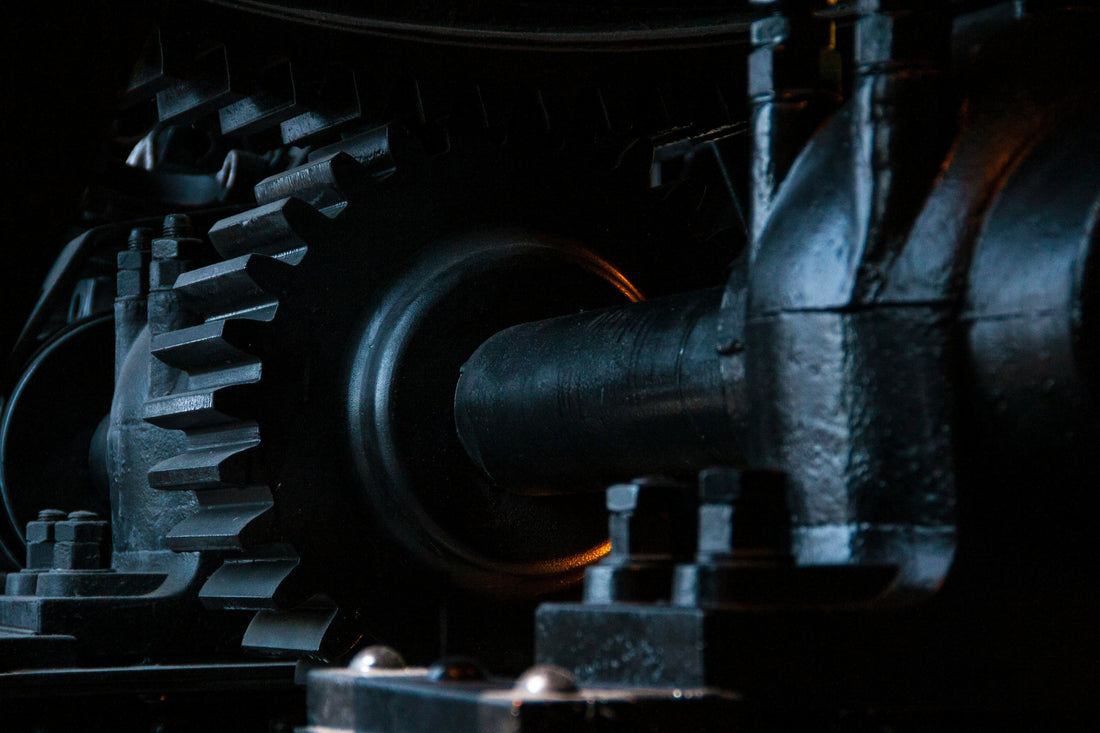

In the world of industrial and marine equipment, precision is everything. A well-aligned system ensures that machinery operates smoothly, efficiently, and with minimal wear and tear. However, misalignment and excessive vibrations are among the leading causes of equipment failure, energy loss, and costly repairs. This is where precision alignment and vibration analysis play a crucial role in maintaining operational efficiency and extending the lifespan of machinery.

Why Precision Alignment Matters

Laser alignment and optical alignment are essential for ensuring that rotating components such as shafts, couplings, and propulsion systems are positioned correctly. Even minor misalignments can cause excessive friction, leading to premature wear, overheating, and increased energy consumption. By using advanced laser and optical alignment tools, technicians can precisely adjust components to ensure smooth operation, improving overall system efficiency and reducing the likelihood of unexpected breakdowns.

The Role of Vibration Analysis

Vibration analysis is a powerful diagnostic tool that detects hidden mechanical issues before they escalate into major problems. Excessive vibrations can result from imbalances, misalignments, looseness, or bearing defects, which, if left unchecked, can significantly degrade machine performance. With the help of state-of-the-art vibration monitoring systems, businesses can proactively identify and correct these issues, minimizing downtime and preventing costly repairs.

Key Benefits of Precision Alignment & Vibration Analysis

- Increased Equipment Lifespan – Proper alignment and early detection of vibration-related issues reduce excessive wear and extend the longevity of machinery.

- Improved Energy Efficiency – Misaligned components create unnecessary friction and energy loss. Correcting alignment and minimizing vibrations optimize power consumption.

- Reduced Maintenance Costs – Preventive maintenance through alignment and vibration analysis helps avoid expensive repairs and unscheduled downtime.

- Enhanced Performance & Reliability – Proper alignment ensures smooth operation, while vibration analysis prevents unexpected failures, improving overall equipment reliability.

- Safety & Compliance – Ensuring that machinery operates correctly reduces the risk of accidents and ensures compliance with safety regulations.

Trust the Experts for Precision Engineering Solutions

Whether you're operating industrial machinery, marine vessels, or other high-performance equipment, investing in precision alignment and vibration analysis is essential. These proactive measures not only enhance efficiency but also save time and money in the long run. Trusting experienced professionals equipped with advanced diagnostic tools ensures that your machinery runs at peak performance with minimal downtime.

If you're looking for reliable laser alignment, optical alignment, or vibration analysis services, contact a professional today to optimize your equipment and improve operational efficiency!